our products

Tungsten carbide burrs and vitrified mounted wheels

Learn more

about our product

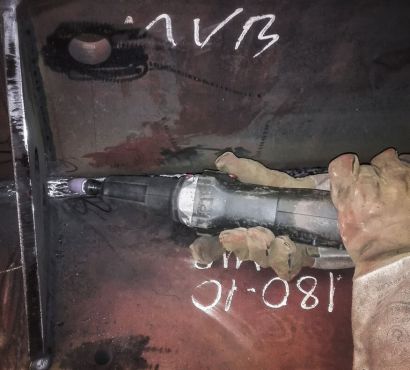

Tungsten carbide burrs and ceramic mounted points are tools used for processing hard to reach places using straight grinders.

Rotary burrs are made of very hard cemented carbide. A top-quality raw material, precise profiling and sharpening on CNC machine tools provide a long time of productive work for the Abras burrs.

Depending on the type of processed material there are different cuts used in our burrs (number and geometry of the teeth). Thus, they can be used for grinding:

- construction steel,

- high-alloy steels and stainless steels,

- steel and cast iron,

- aluminum and non-ferrous alloys,

- hard plastics.

There are several standard shapes used in our rotary burrs program:

- shape A – cylindrical without front cut

- shape B – cylindrical with front cut

- shape C – cylindrical rounded

- shape D – spherical

- shape E – oval

- shape F – ball nose tree

- shape G – pointed tree

- shape H – flame

- shape L – conical rounded

- shape M – conical pointed nose

Alternatively to rotary burrs, especially for processing hard materials, we offer mounted points – vitrified or resin bonded (resinoid). Like other tools of this type, they come in a variety of grains and hardness. These parameters are carefully selected for a specific application.

The most common shape of the vitrified molding machines is a cylinder, however, other shapes are also availble.

Schedule a visit of our technical sales advisor

Chosen products

Below, we present selected types of burrs and mounted points with typical examples of applications.

Abras rotary burr

12,7x25x6mm

Product photo

Welds processing

Abras rotary burr

12,7x25x8mm / 150mm

Product photo

Inner surface processing

Abras tungsten carbide burr

1,2x15x3mm

Product photo

Refurbishing drilling

Abras mounted wheel

40x40x6mm

Product photo

Inner surface processing

Abras vitrified wheel

20x40x6mm

Product photo

Edge processing

Abras vitrified wheel

20x40x6mm

Product photo

Welds processing